Stainless Steel Castings

Stainless Steel material is very common used in the investment casting process, and also applied to wide industries.

Choose the material stainless steel have some reasons:

The base alloy elements of any nickel-base or stainless steel casting are chromium, nickel, and molybdenum. These three components will determine the casting’s grain structure and mechanical properties, and will be instrumental in the casting’s ability to combat heat and/or corrosion.

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. However, this is not an absolute. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

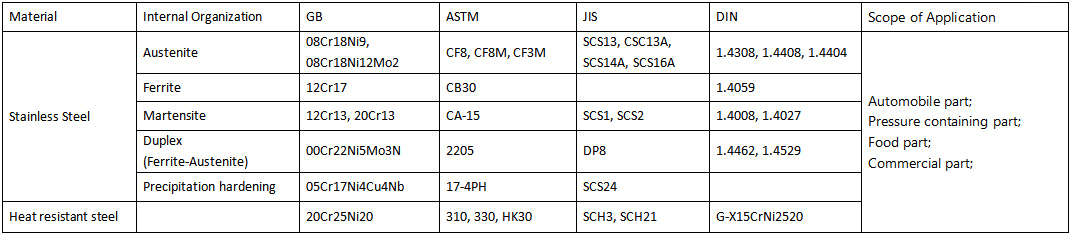

You can refer to the following standards and internal organizations to find your needs: